Type of event: Industrial visit

Date(s): 14th Feb 2025

Time: 9:30 am to 3:00 pm

Venue: Industries

Organizer: Dr Shalu and Dr Sonika

Mode: Offline

Objectives: To provide exposure to the students about industries.

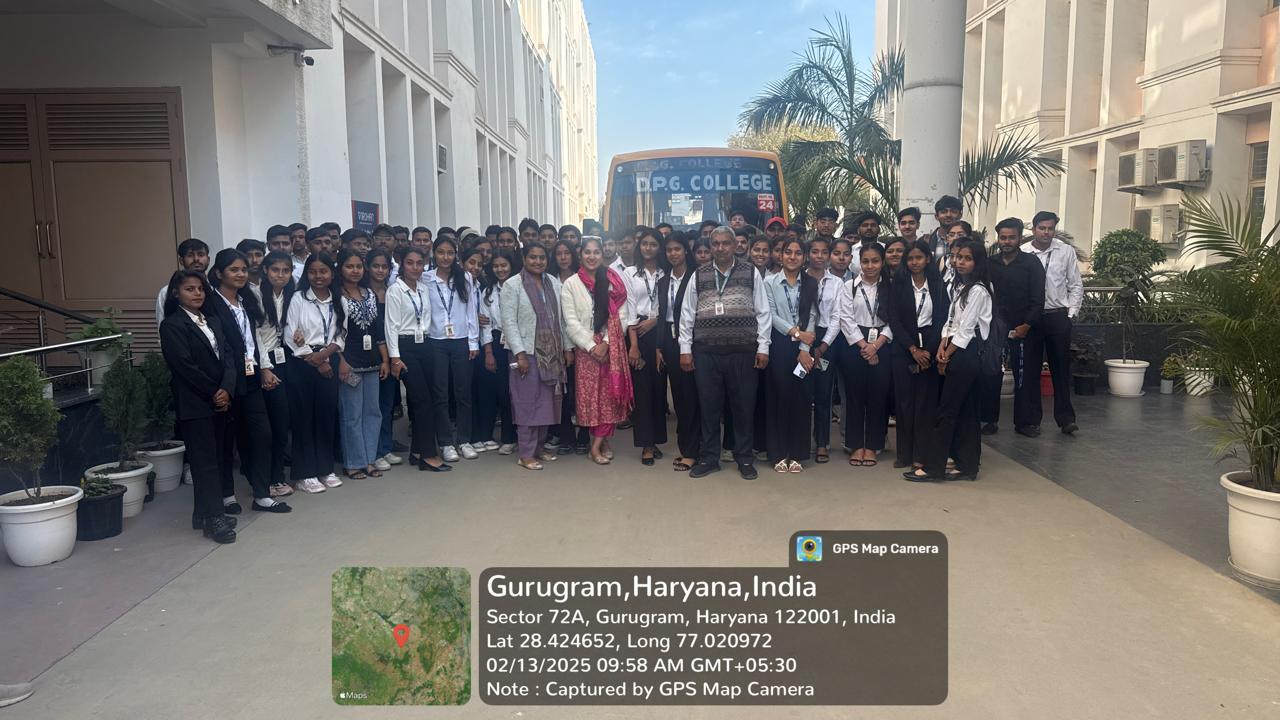

Participants: All the students of BBA First year, DPGITM

Department of management studies at DPGITM, Gurgaon organized an industrial visit for its students of BBA.

The objective of the industrial visit was to help students to combine their theoretical knowledge of business operations with the practical knowledge of its actual functioning and to provide the students with an opportunity to learn practically through interaction and working methods. It was a worthwhile learning experience for the students as they gained an understanding of how an industry operates. Learning about the Operations, Management, Good Practices, Technology Involved, and Supply Chain Management exposed students to a plethora of relevant fields.

Company Overview:

Yakult Danone India Pvt. Ltd. is a 50:50 joint venture between Yakult Honsha of Japan and Groupe Danone of France, both renowned global leaders in probiotics. Established in 2005, the company introduced its flagship probiotic drink, Yakult, to the Indian market in 2007. The Sonipat facility is ISO 9001:2008 and HACCP certified, underscoring its commitment to quality and safety in manufacturing.

Visit Highlights:

- Welcome and Introduction: Upon arrival, the students were warmly received by the Public Relations team. The visit commenced with an informative presentation detailing the history of Yakult, the science behind its probiotic benefits, and the company’s journey in the Indian market. This session provided a comprehensive understanding of Yakult’s global presence and its dedication to promoting health through probiotics.

- Factory Tour: Following the presentation, students were guided through the state-of-the-art manufacturing facility. The tour encompassed various stages of production:

- Seed Room: The process begins here with the cultivation of the unique probiotic strain, Lactobacillus casei strain Shirota.

- Culture Room: The cultivated bacteria are then added to a pasteurized milk solution in large culture tanks, where they ferment until reaching optimal levels.

- Mixing Room: The fermented solution is blended with a specific syrup to achieve the desired taste profile.

- Quality Control Room: Rigorous quality checks are conducted to ensure the final product meets stringent safety and quality standards.

Throughout the tour, students observed the highly automated processes that minimize human intervention, thereby maintaining exceptional hygiene and efficiency standards.

- Interactive Session: The visit concluded with an interactive Q&A session, where students engaged with company representatives, delving deeper into topics such as supply chain logistics, marketing strategies, and career opportunities within the organization.

Learning Outcomes:

This industrial visit provided students with valuable exposure to:

- The practical application of biotechnological principles in large-scale production.

- The importance of stringent quality control measures in the food and beverage industry.

- The integration of automation and technology to enhance manufacturing efficiency.

- Corporate strategies for market development and consumer engagement.

Such experiences bridge the gap between theoretical knowledge and real-world applications, equipping students with insights that are crucial for their professional development.